11 May 2017

5 Typical causes of workplace electrical incidents

Unsafe electrical safety practices in the workplace can kill. Healthy Working Lives reveal that each year around 1000 electrical shocks or burns are reported to the Health and Safety Executive (HSE), 30 of which are fatal. For those who escape this fate, their future is still often blighted by permanent injuries.

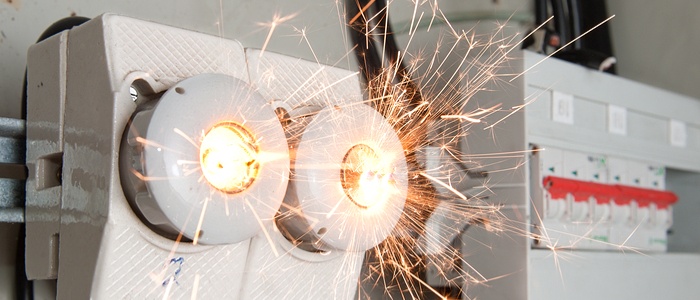

There are still too many unsafe working practices which could result in fatalities arising from electric shocks. Here are five typical examples which could cause an electric shock and/or fire.

1. Replacing a continually tripping circuit protective device with one of a higher rating

In offices, it is common for too many items of electrical equipment to be added to an electrical circuit, which can cause the protective devices to trip due to overloading. Unfortunately, the ‘solution’ to this is often to use an overrated protective device to stop the nuisance tripping. Cables are designed to carry a certain amount of current and the protective devices are selected to protect them from being overloaded. However, if the protective device is replaced for one of a higher rating, there is the potential to exceed the cable’s current carrying capacity leaving it vulnerable to overload. This can result in the cable potentially melting or catching fire.2. Live exposed parts of damaged accessories such as light switches and socket outlets

Live exposed parts are commonly caused by electrical accessories being placed in an unsuitable area where they are damaged by being struck by objects. Another frequent risk is caused by missing covers giving access to internally live parts. Frequently used plastic socket outlets are particularly vulnerable to damage. This often caused by users tugging plug tops out of the socket by the lead, or by banging the plug top into the socket outlet. Eventually, the plastic socket outlet will crack, exposing live parts. Your inspection and testing provider should be able to advise you if your electrical accessories are vulnerable to damage and require relocation. They will also advise which socket outlets are deteriorating due to wear and tear. Electrical Inspection and Testing: an easy guide to fulfilling your duties3. Inadequate earthing

Equipment or accessories can become ‘live’ under a fault condition when there is poor, or no means of, earthing to the equipment. This is often encountered in older systems and especially on lighting circuits with metallic fittings. However, more recently, we have seen cheap imported equipment being used with no earthing provisions.4. Inadequate protection against water ingress for the environmental conditions

Where the water ingress protection of electrical equipment, or its control panel, has not been selected correctly or has deteriorated, water will penetrate and potentially cause a short circuit condition/loss of production/nuisance tripping or fatality by electric shock. This is often seen within the food industry, where jet washers are used to wash down equipment.5. Poor maintenance of electrical installation and equipment

Where a site has little to no maintenance carried out, the electrical installation will deteriorate unnoticed. It is common to find missing distribution board covers exposing live parts, missing or damaged lids to connection boxes, terminal boxes, broken accessories, loose connections, poor installation methods etc. All of this represents a potential fire and/or shock risk. As you can see, common workplace practices can quickly escalate into serious injuries, or worse, fatalities caused by electrical shocks. However, electrical faults don’t just cost lives. They can cost businesses too, as well as resulting in both company and personal prosecutions for those responsible. We can provide an ebook: Electrical Inspection & Testing: A Guide to Fulfilling Your Duties covers all you need to be aware of when it comes to electrical inspections - an important element in the proper maintenance & prevention of electrical installations and equipment in the workplace.Recent Posts

Ascend Broking

ASCEND BROKING GROUP LAUNCHES ASCEND RISK

Ascend Broking